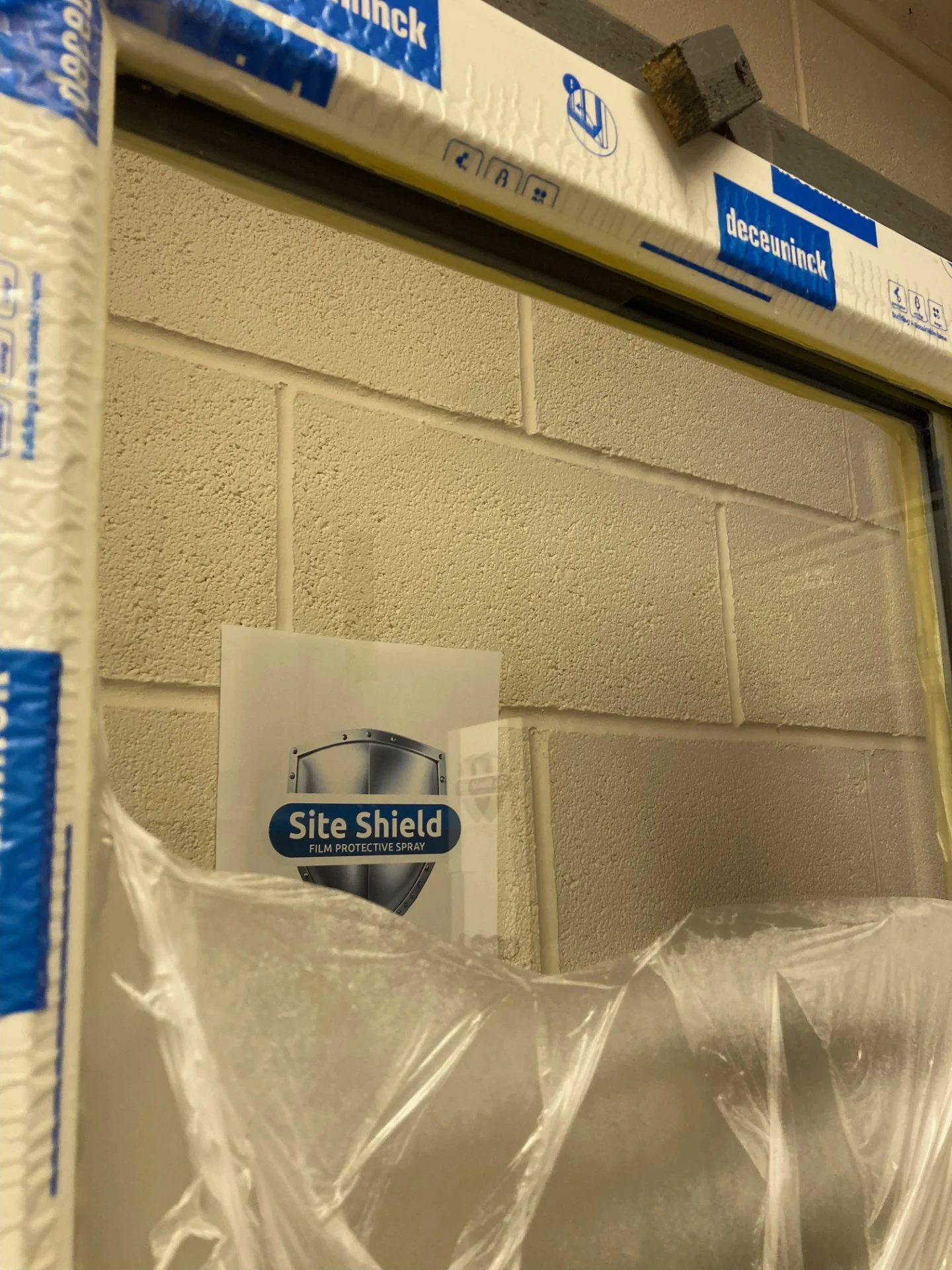

Product Intent

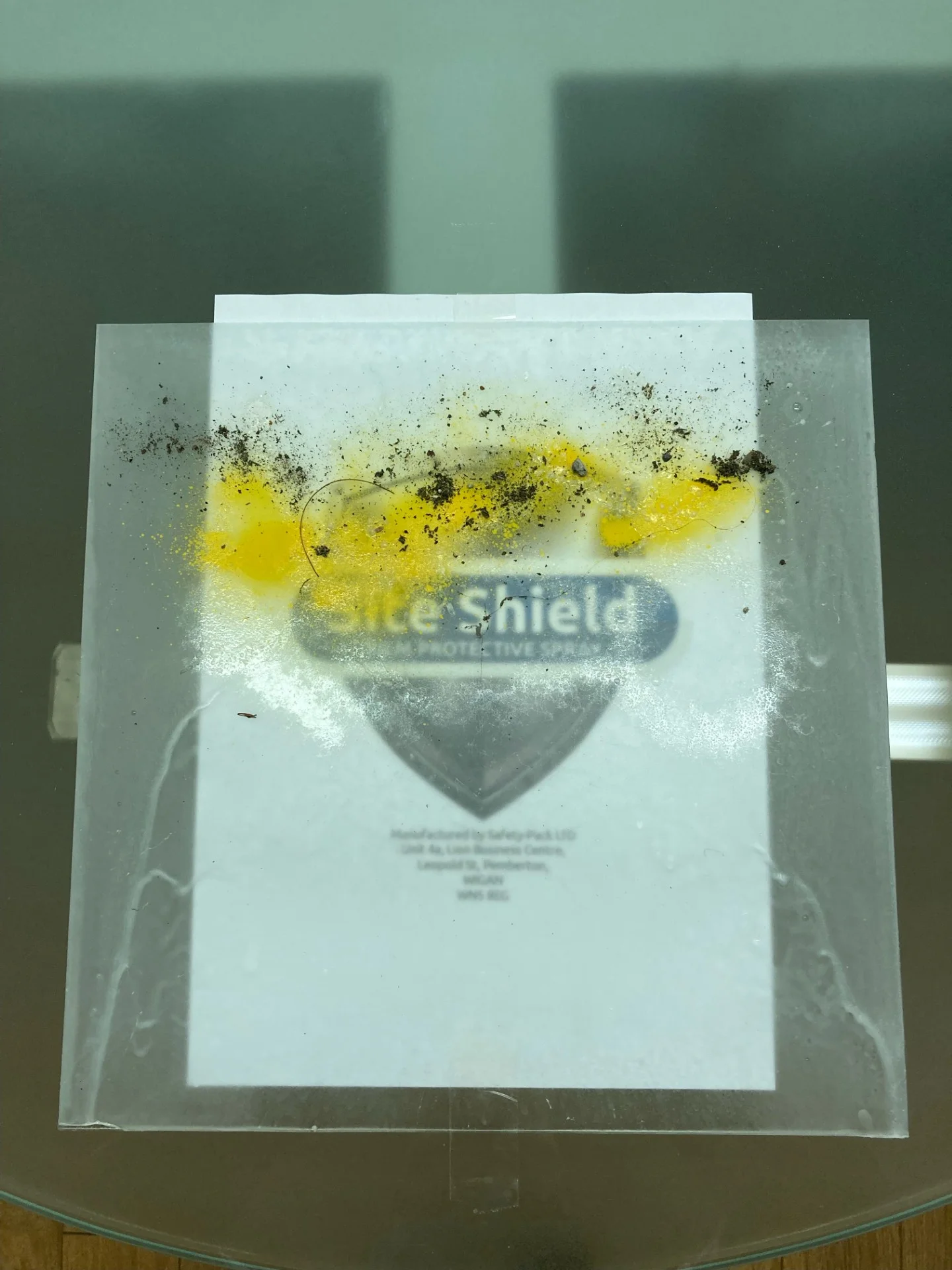

Once applied, Site Shield provides a barrier against detritus and other forms of debris and prevents it from bonding directly to glass. After the coating system has performed its intended role, it can be quickly and easily removed from the surfaces onto which it has been applied. Our rational behind the development of Site Shield was to reduce the time of application, provide the necessary levels of protection to surfaces and keep the removal time to a minimum. We hope that Site Shield meets your expectations and offers a new tool to overcome the unnecessary and costly consequences of glass refurbishment and replacement.

Application

In order to achieve the intended results, we recommend the following application process:

- Ensure that the area to be coated is dry and free of debris.

- Pre-wipe any areas of exposed uPVC with the provided wipe (Wipe A) See Note.

- Hold the aerosol up to 300mm away from the surface.

- Spray horizontally in a left-to-right direction, covering the full surface.

- Allow 10-30 seconds between each coat – dependent on ambient temperature.

- We recommend three coats to provide full coverage, but more can be applied.

- Remove any overspray from bare uPVC with the provided acetone wipes (Wipe B) See Note.

- The applied coating will be fully cured after 4-hours.

Note: Should uPVC elements of the window frame not have the typical factory applied film tape or, if there are areas of the uPVC which are not covered by the film tape, care should be taken to pre-protect and to remove any overspray of Site Shield from the bare or unprotected areas of the uPVC.

It is therefore necessary to ensure that Steps 2 and 7 above are undertaken in full.

If Site Shield is left to dry on bare/unprotected uPVC for more than 24-hours, the provided acetone wipes (Wipe B) and a light abrasive agent such as T-Cut may be required to restore plastics back to original form.

Disclaimer: Site Shield takes no responsibility should these necessary steps not be followed.

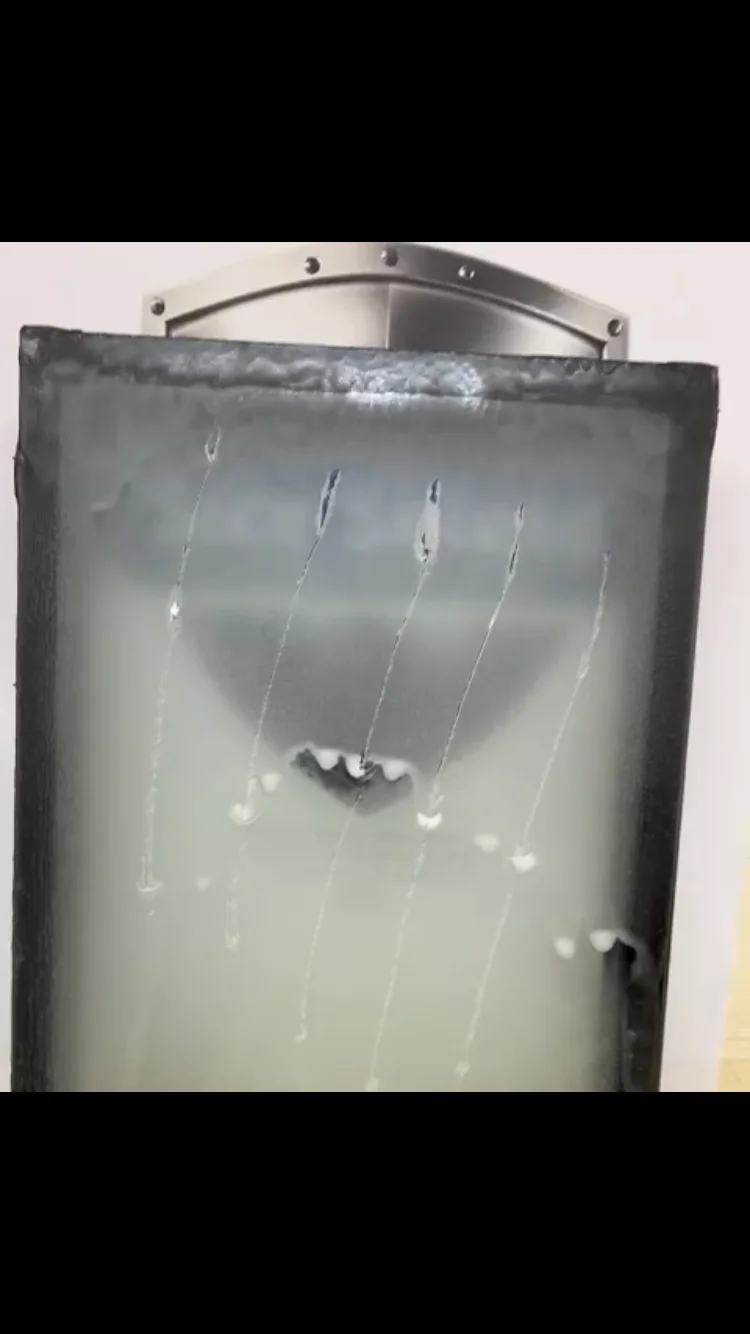

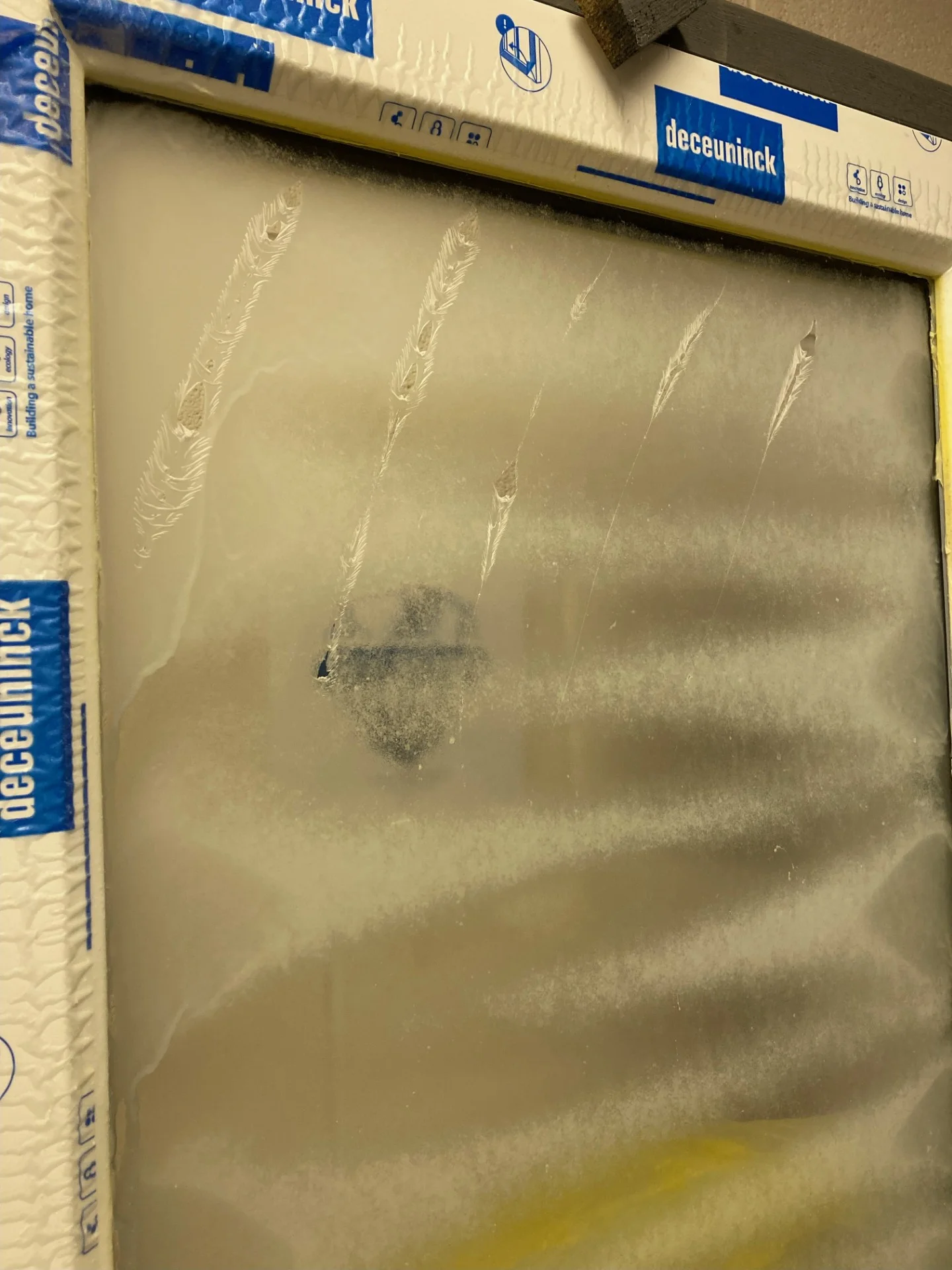

Removal

To effectively remove the product from the surface it has been applied to take the following steps:

- Starting from a corner, begin to remove the film coating.

- To aid in continuous film removal, keep as close to the surface as possible whilst removing.

- Any residual film coating can be easily removed with an acetone wipe.

- Buff glass with a clean dry cloth.

- Removed film can be disposed of in a similar manner to other plastic materials on site.

PLEASE SEE SAFETY PROVISIONS ON REVERSE

Safety

Always read the product label, including storage instructions.

Adhere and obey site specific health and safety policies.

Personal Protective Equipment must be worn, including eye protection, hand protection (nitrile gloves) and an FFP2 face mask. Exposed skin in the immediate area of the spray pattern should be covered i.e., arms.

For Glass surfaces only, do not spray on plastics, painted/varnished or, porous surfaces.

Should you have any questions or queries regarding Site Shield please contact us on:

Email: sales@siteshield.uk

Freephone: 0800 652 8099

Site Shield: The Smarter Way to Protect Surfaces During Construction

At Safety Pack, we know how much effort goes into protecting materials on-site. Whether you’re dealing with glass panels, metal frames, woodwork or ceramic features, keeping surfaces clean and unmarked during installation is a priority — and too often, a pain. That’s why we developed Site Shield.

Originally launched as a spray-based solution to reduce marring on glass during manufacturing and installation, Site Shield showed strong technical performance. Customers appreciated how well it protected surfaces without leaving residue or damaging finishes. But there was one clear challenge: cost.

Many users loved the concept but found the spray format too expensive to justify, especially for high-volume projects. So, we listened.

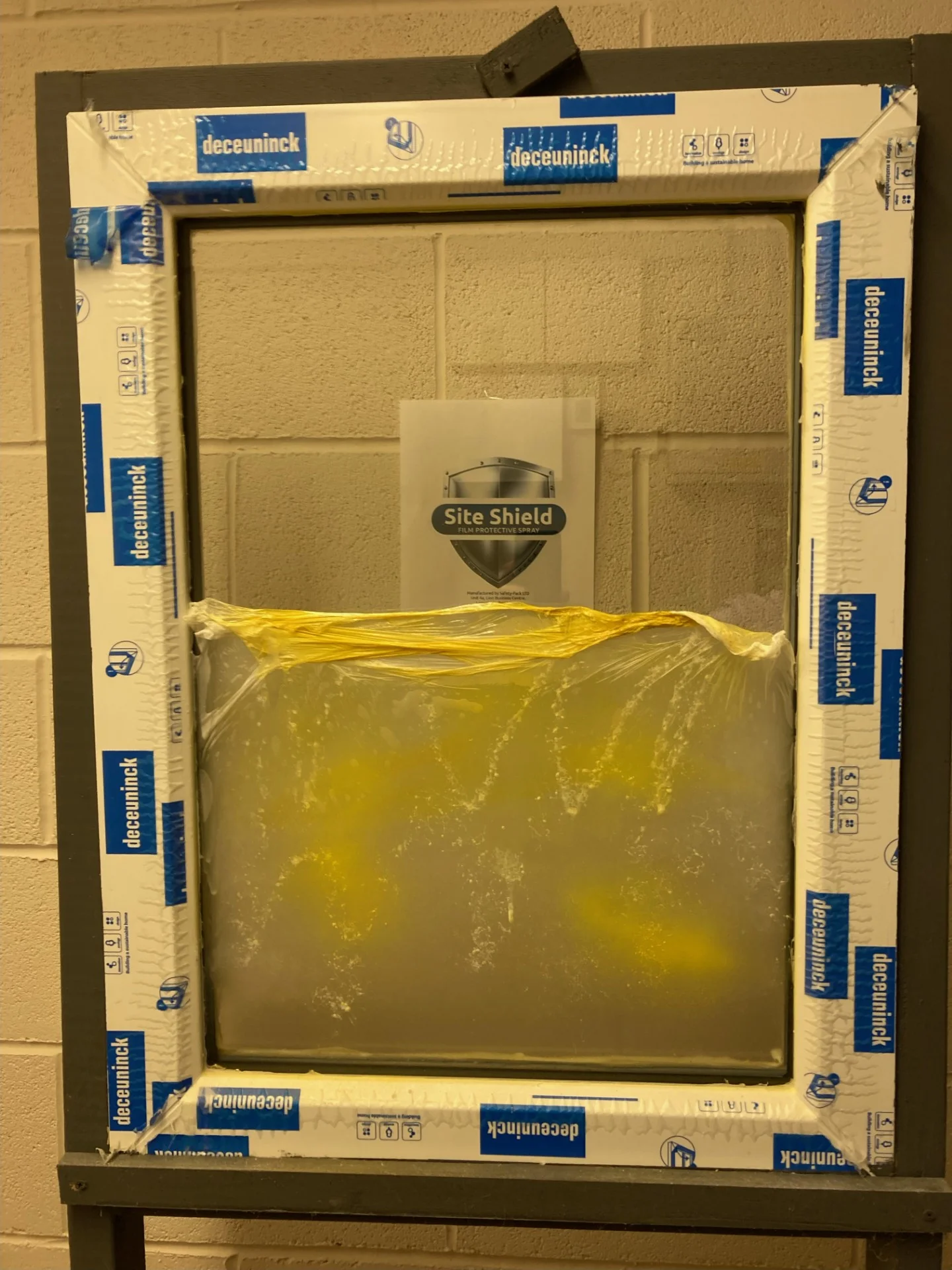

Re-engineered for Value, Tested for Performance

Based on this feedback, we adapted Site Shield into a new format — a 35-micron self-adhesive film. The goal was simple: deliver the same quality protection at a price point that works on real sites, for real jobs. And the results have hit the mark.

Here’s what you get with our updated Site Shield system:

• No delamination: Once applied, the film stays intact — no peeling, lifting or curling.

• 24-month UV stability: Tested at 400nm at 28°C under visible light conditions, Site Shield holds up for two full years outdoors.

• Clean removal: No adhesive residue is left behind on any surface after removal.

• Multi-surface protection: Glass, PVC, wood, metal, ceramics — Site Shield covers them all.

This makes it ideal not just for housebuilders and glaziers but also for renovation teams, rendering crews, decorators and anyone needing temporary protection that doesn’t come with long-term cleanup.

A Better Alternative to What’s Out There

Let’s be real: a lot of surface protection film on the market just doesn’t last. Common products often break down within 6 to 12 months and many suffer from delamination or leave behind adhesive traces that take hours to clean up. We’ve seen it happen, and we know the cost adds up — in wasted labour, damaged finishes and dissatisfied clients.

Site Shield is engineered to avoid those pitfalls. It’s designed to be durable, reliable and affordable. After extensive testing and customer feedback, we’re now moving into a full market evaluation phase. That means we’re producing 500 sample rolls, available now for select customers to try out.

Each roll is:

• 600 mm wide

• 35 microns thick

• 50 metres long

We’ve targeted a cost of £10.25 per roll ex works. Based on our research, this makes Site Shield cheaper than other options on the market, with a longer life span and higher performance. If that price is in line with what you’re currently paying, we’d be happy to supply a sample for you to evaluate. Simply let us know via email.

Of course, we can also offer custom roll sizes depending on demand — just ask.

What Makes Site Shield Different?

The biggest reason to choose Site Shield is peace of mind. When you apply it, you know it’ll do the job and come off clean. You won’t have to worry about UV damage breaking it down prematurely or sticky residue costing you hours in rework.

It also looks clean and professional on-site. If you’ve walked past a new build or refurbishment project recently and seen a clear plastic sheet over the windows or walls — that’s the idea. Only with Site Shield, you get a product that won’t start failing in a few months’ time.

We’ve taken the time to test it across multiple surface types, under varying conditions, and the results speak for themselves. From the first peel to the final removal, Site Shield is built to save you time, money and hassle.

Ready to Try It?

If you’re already using protection film or sheets on-site, Site Shield could be a smarter, longer-lasting replacement. And if you’ve had bad experiences with delaminating plastic in the past, this is your chance to switch to something that’s built to perform.

We’re offering a limited batch of sample rolls during our evaluation phase. If you’re interested in receiving one, just email us and we’ll take care of the rest.

We won’t waste your time with a product that doesn’t match your expectations on price or performance. But if it sounds like a fit — and you’re ready to upgrade your protection game — we’d like to hear from you.

Site Shield – Overview

Product Specifications

12 x 350ml spray cans (covering approximately 90m2 box / 7m2 can)

Spray application via a lightweight, easy to use 350ml spray can

Operating temperatures from -18°C to + 46°C

UV stable

100% waterproof – Intended for internal and external use

Will protect glass from: paint, mortar, plaster, sand, dust, adhesives and even bladed articles!

Significant reduction in site waste, helping to reduce carbon footprint

Will not delaminate from glass surface, offering a long-lasting protection